KUKA KR210-2

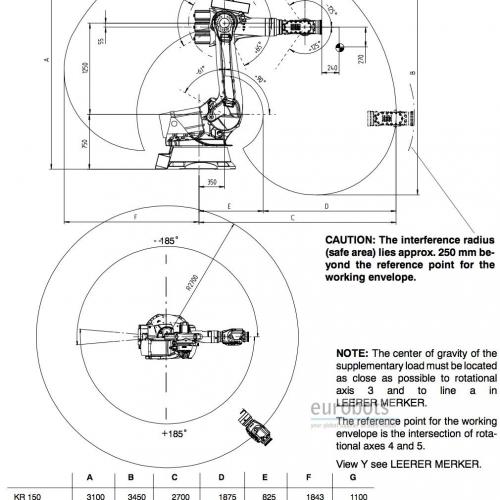

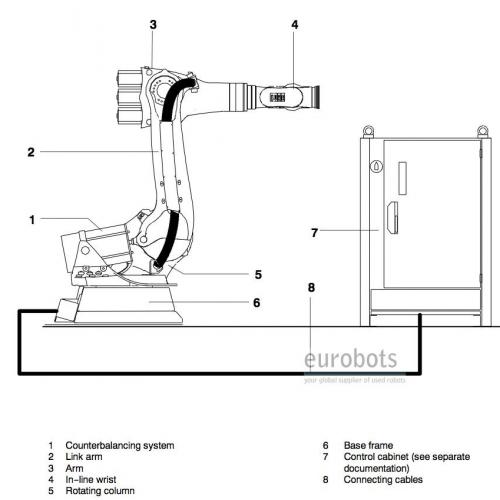

Heavy payload 6 axis industrial robot available in three versions attending to the arm reach / payload: KR 210-2 (2700 mm / 210 kg) , KR 210L180-2 (2900 mm 180 kg) , KR 210L150-2 (3100 mm / 150 kg).

Suitable for machining, spotwelding, machining, handling and palletizing applications.

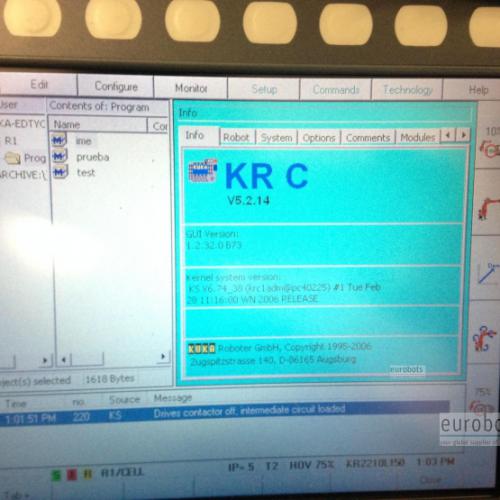

Equipped with the KRC2 controller available in two versions attending to the software version: 4.1.7 running on Win95 or 5.2.9 on WinXP platform.

The KR C2 robot controller makes programming easier with its Microsoft Windows interface. It is expandable, can be integrated into networks via a bus, and contains ready-made software packages.

KR C2 features

- Open, network-capable PC technology

- 2 free slots for external axes

- DeviceNet and Ethernet slots for common bus systems (e.g. INTERBUS, PROFIBUS, DeviceNet) provided as standard

- Motion profile function for optimal interaction between the individual robot motors and their velocity

- Floppy disk and CD-ROM drives for data backup

- Facilities such as remote diagnosis via the Internet

- Simple operation and programming via KUKA Control Panel (KCP) with Windows user interface

- Compact control cabinet

- Ergonomic KUKA Control Panel (KCP)

Robot Info

- Maximum Load of Robot: 210/180/150 Kg

- Maximum Reach: 2700/2900/3100 mm

- Repeatability: 0.15

- Controller: KR C2

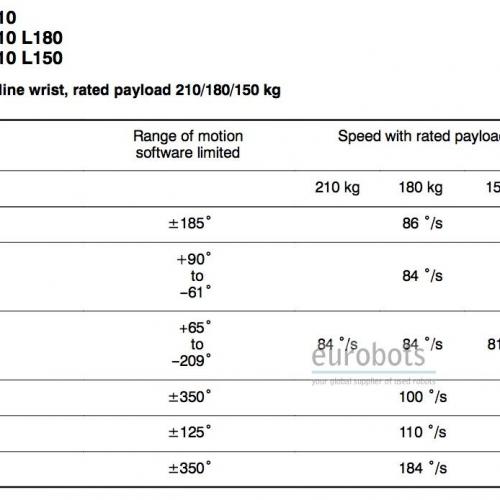

Axis Speed in º/s for the models: KR 210-2 / KR 210 L180-2 / KR 210 L150-2

- Axis 1: 86º/s (all 3 models)

- Axis 2: 84º/s (all 3 models)

- Axis 3: 84º/s 84º/s 81º/s

- Axis 4: 100º/s (all 3 models)

- Axis 5: 110º/s (all 3 models)

- Axis 6: 184º/s (all 3 models)

Range of motion (Axis 1 to 6)

- Axis 1: +- 185º

- Axis 2: +90 to -61º

- Axis 3: +65º to -209º

- Axis 4: +-350º

- Axis 5: +-125º

- Axis 6: +-350º

Applications

Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts , Glueing - Adhesive bonding , Stud welding , Plasma cutting

Pictures

Videos

Diagrams

English

English

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa