General information

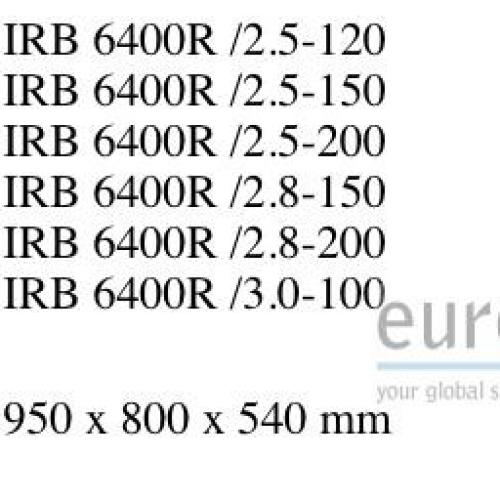

Year 2002. New mechanics in the first three axis compared to its predecessors M97 and M98. The 6-axis IRB 6400 manipulator and S4C robot controller provide short and precise cycle times, rapid change-overs and consistently high process precision. These robots are suitable for press tending and handling due to its long arm reach (3 meters).

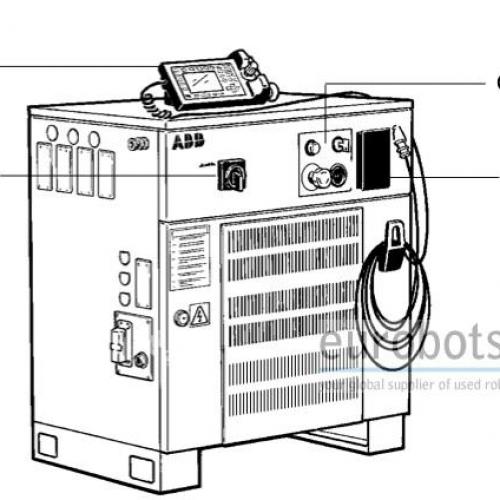

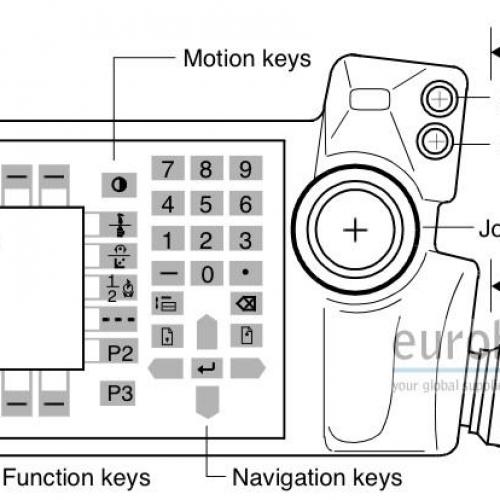

S4C controller - Enhanced communication capabilities: CAN-bus, Interbus- S slave, Allen Bradley remote I/O, Ethernet...

RAPID instructions for enhanced programming capabilities.

Adaptability

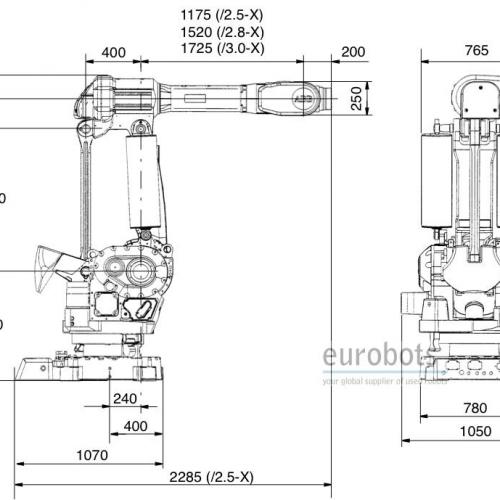

IRB 6400 is designed to be compact with a small interference radius to ensure flexible installations in areas with high density of production equipment.

The process media, which is integrated through the robot base is easily exchanged and changing from a

2.5 to 3 meter overarm takes less than 30 minutes.

The robot can be calibrated one axis at a time to ensure a quick return to full production.

Robot Info

* Number of axis: 6

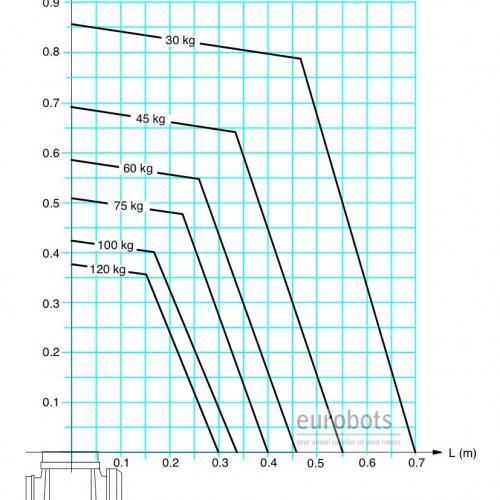

* Maximum Load of Robot: 100 Kg.

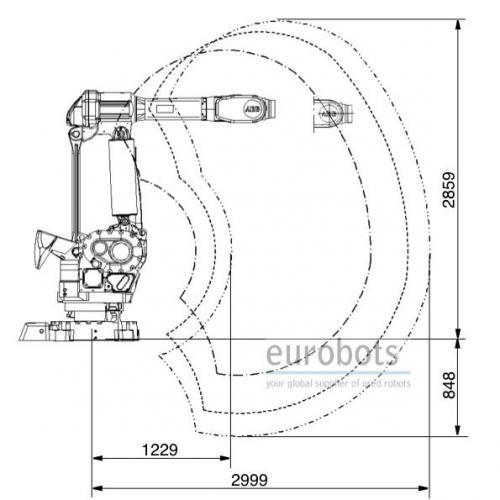

* Maximum Reach: 3000 mm.

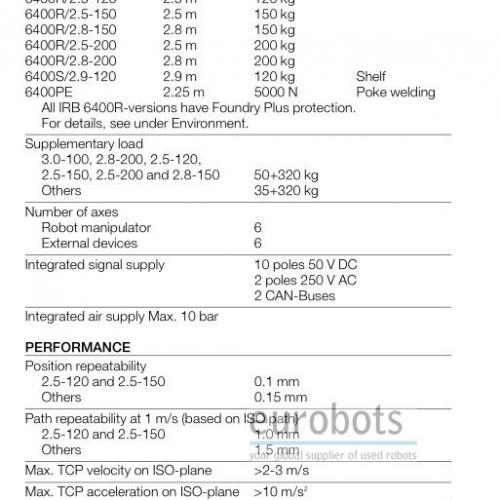

* Repeatability: 0,2 mm.

* Controller: S4C

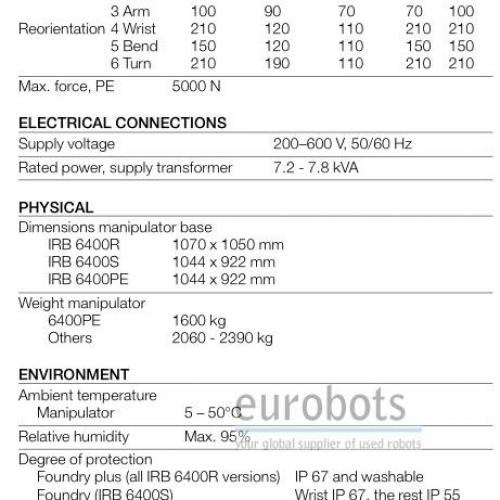

Robot Motion Speed

* Axis 1: 110º/s

* Axis 2: 100º/s

* Axis 3: 100º/s

* Axis 4: 210º/s

* Axis 5: 150º/s

* Axis 6: 210º/s

Robot Applications

* Spot welding

* Press tending

* Material handling

* Machine tending

* Palletizing

* Assembly

アプリケーション

スポット溶接 , プレステンディング , パレタイズ , 部品のロードとアンロード , 機械加工 , 部品の取り扱い , 接着-接着剤による接着

写真

ビデオ

設計図